Inventory

Inter-Site Stock Transfer (Branch to Branch)

This process enables transfer of item(s) from a selected warehouse in a particular site to a warehouse in a different site.

You will need to ensure that the Company Configuration Enforce In-transit flag is set to 'No' to be able to complete this process.

Unlike in the Inter-Bin Stock Transfer process, in this process, the Source warehouse will be different from the Final/Destination warehouse.

Take note of the important notes below:

- You will need to ensure that the Company Configuration Enforce In-transit flag is set to 'No' to be able to complete this process.

- This will be a direct transfer to a different warehouse within a different site, and no receiving is required.

- Ensure that you select the correct quantity to be transferred.

- Ensure that you select from the correct batch number (C-Class item) or select the correct serial number (A or B-Class item) to be transferred.

- Ensure that the correct final/destination warehouse in the new destination site is selected.

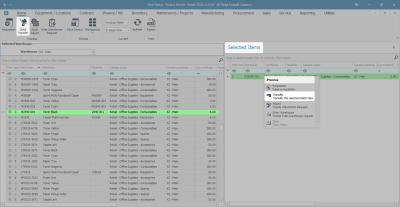

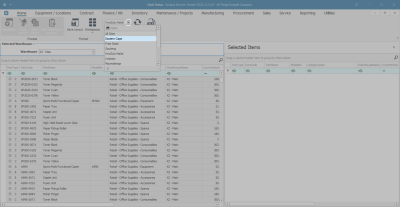

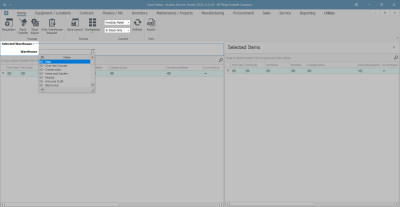

Ribbon Select Inventory > Stock

- The Stock Status screen will be displayed.

Transfer - C-Class Item

Select Site and Status

- Select the source location or Site where the C-Class stock is currently being stored.

- In this example KwaZulu-Natal is selected.

- The screen status will default to In Stock only.

- This status can remain selected.

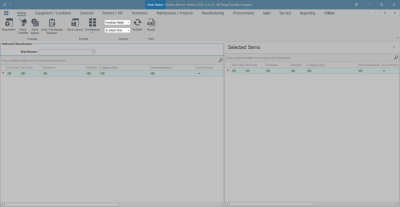

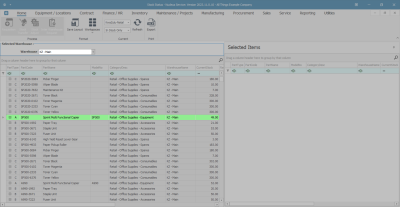

Selected Items panel

- Click on the Selected Items tab.

- The Selected Items panel will be expanded.

- Dock this panel to make it easier to work in.

Refer to Docking Panels and Save Layout for detailed handling on these topics.

Note: You will see that this Selected Items panel contains exactly the same column details as the Selected Warehouse panel.

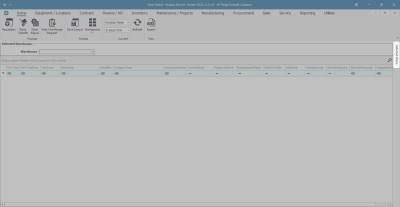

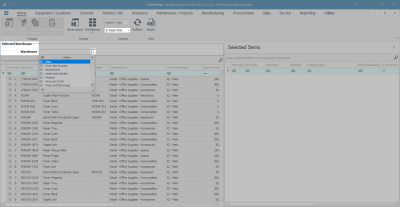

Select Source Warehouse

- Click on the drop-down arrow in the Warehouse field and select from the list the 'source warehouse' (where the stock is currently being stored).

- In this image, KZN Main has been selected.

- The Selected Warehouse frame will populate with all the items currently in stock in that warehouse.

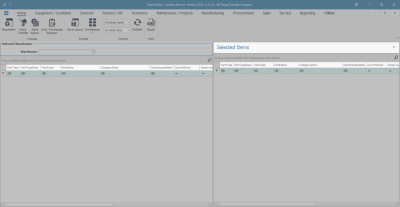

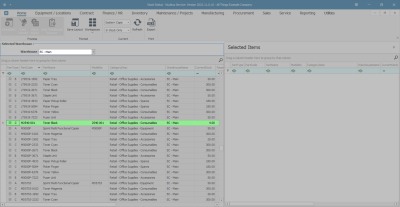

Select C-Class Items for Transfer

- Click on the item line of the C-Class part that you wish to transfer.

- Drag and drop this line into the Selected Items frame.

Transfer Selected Item(s)

- The Selected Items panel will now contain the item details.

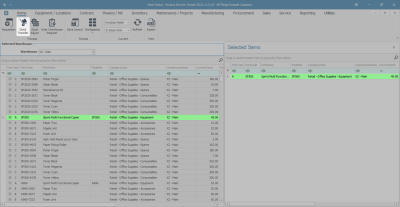

- Method 1

- Right click in the row of a selected item line.

- A Process menu will pop up.

- Click on Transfer - Transfer the selected batch item.

- Method 2

- Click on the item line in this frame, then click on Stock Transfer.

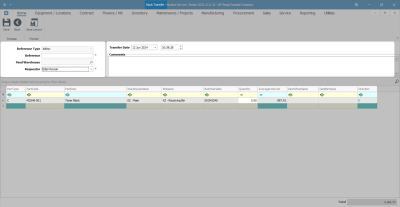

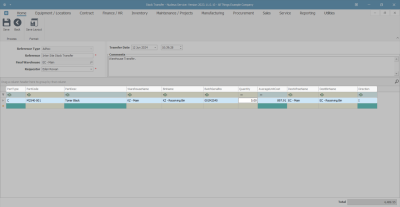

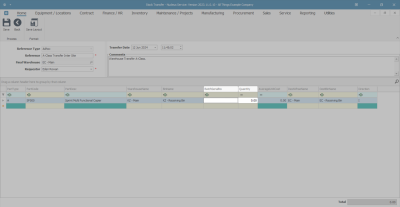

Transfer Details

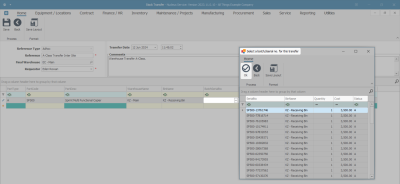

- The Stock Transfer screen will be displayed.

- Reference Type: This will auto populate with Adhoc.

- Reference: Type in your reference for this stock transfer.

- Final Warehouse: For this process, the final warehouse will be the same as the Destination warehouse. The Final warehouse is only different when using the In-Transit warehousing process. (We will address this field in the next image.)

- Requestor: This will auto populate with the person currently logged on to the system. You can click on the drop-down arrow and select an alternative person if required.

- Transfer Date and Time: This will auto populate with the current date and time.

- Date: You can either type in or click on the drop-down arrow and use the calendar function to select an alternative date if required.

- Time: You can either type in or use the directional arrows to select an alternative time if required.

- Comments: Type in a comment relating to the reason for the stock transfer.

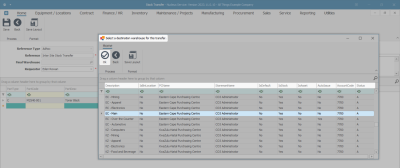

Select Final Warehouse

- Final Warehouse: Click on the search button in this field.

- The Select a destination warehouse for this transfer screen will pop up.

- Click on the row selector in front of the warehouse that you wish to be the final destination warehouse.

Note: As you are doing an inter site stock transfer - ensure that you select a different final warehouse and site from the source warehouse and site.

-

Click on Ok.

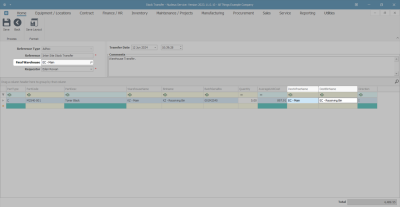

- As the Final Warehouse field populates with the selection made in the previous step, the Destination Warehouse Name column in the parts data grid will also populate with the selection made.

Select Destination Bin

- Note: If there is only 1 bin linked to the final warehouse then the Dest Bin Name field will also populate with that 1 bin name. If, however there are 2 or more bins linked to the Destination Warehouse than the system will leave the field blank for you to make the correct bin selection.

- In this example, there is only 1 bin linked to the EC Main warehouse therefore the Dest Bin Name field has been populated with that one bin name.

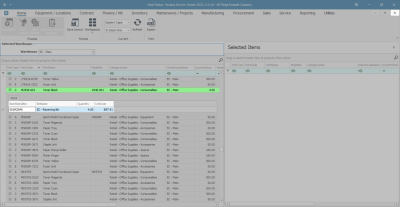

Parts Data Grid

- Part Type: This will auto populate with part type code of the item type selected in the Stock Status screen.

- Part Code: This will auto populate with the part code of the item selected in the Stock Status screen.

- Part Desc: This will auto populate with the part description of the item selected in the Stock Status screen.

- Warehouse Name: This will auto populate with the source Warehouse Name selected in the Stock Status screen.

- Bin Name: This will auto populate with the Bin Name, only if there is 1 bin linked to the selected warehouse. Otherwise,

- Click in this field to reveal an ellipsis button.

- Click on this button.

- From the Select a destination bin for this part transfer screen that pops up, select the correct bin location name.

- Click on Ok.

- If there is only 1 batch of the selected item available in the selected bin, then the Batch Serial No field will populate with that batch number. However, If there is more than 1 batch then the system will leave this field blank for you to select the batch number.

- In this example, there is only 1 batch available to select from, therefore the Batch Serial No field is populated.

- You will note that the Quantity field will initially auto populate with the total quantity of items available in all the batches in the selected source warehouse bin.

- The Average Unit Cost field will be populated with the average cost of all of the selected item type in the selected bin.

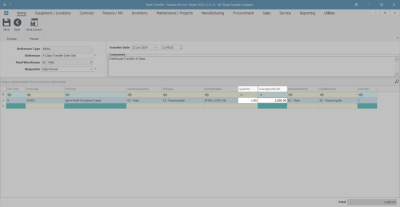

Select Quantity

- Click in the Quantity field and either type in or use the directional arrows to select the amount of items to be transferred.

Note: The system will not allow you select for transfer more than the quantity available in the batch.

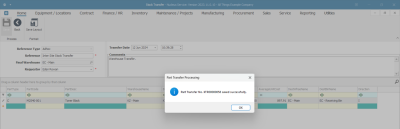

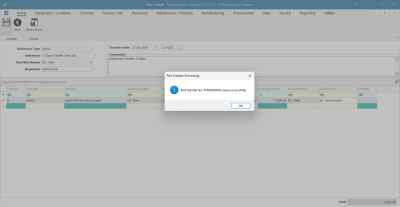

Save Transfer

- Click on Save.

- A Part Transfer Processing message box will pop up informing you that:

- Part Transfer No. [ ] saved successfully.

- Click on OK.

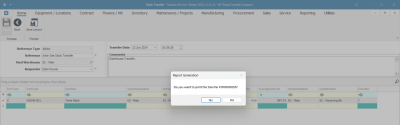

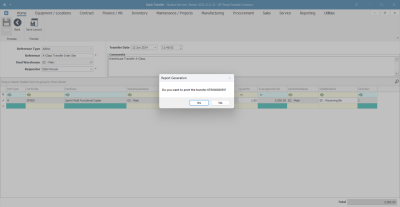

Print Transfer Note

- A Report Generation message box will pop up asking -

- Do you want to print the transfer [ ]?

- Click on Yes.

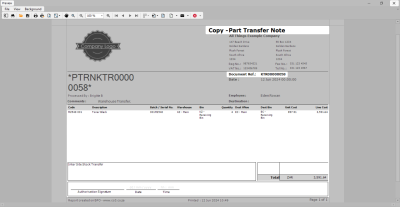

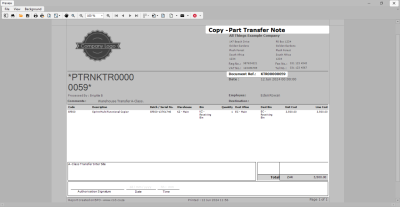

The Report Preview screen will be displayed.

- You can see that one item has been transferred from

- the KZN Main and KZ Receiving bin into the

- EC Main warehouse and EC Receiving Bin.

- From here you can View, Print, Export or Email the Part Transfer Note.

- Close the Report Preview screen when you are done.

- You will return to the Stock Status screen.

View C-Class Item in Destination Warehouse

Select Destination Site

- Click on the drop-down arrow in the Site field and select the destination Site.

- In the example above, the destination site selected was Eastern Cape.

- The Status can remain as In Stock Only.

Select Destination Warehouse

- Click on the drop-down arrow in the Warehouse field and select the destination warehouse.

- In the example above, the destination warehouse selected was EC Main.

View Transferred Stock

- The Selected Warehouse frame will populate with a list of the In-Stock items.

- Click on the expand button in the item line.

The Stock frame will be expanded. Here you can see that:

- C-Class item - [M2540-001],

- from BatchSerial Number [001M2540 - the batch number as selected above]

- has been transferred to Bin Name [EC Receiving Bin - the bin name as selected above].

- Close the screen when you are done.

Transfer A or B-Class Item

To transfer an A or B-Class item, you will follow almost exactly the same process as for above. The only differences are found in the BatchSerialNo, Quantity and Average Unit Cost fields in the Stock Transfer screen.

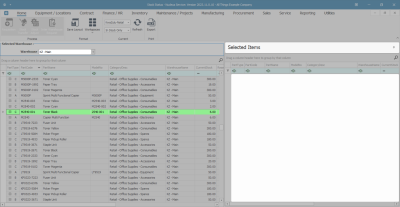

Select Source Site

- Select the source site (the site where the A or B-Class item is currently stored).

- In this image, KwaZulu-Natal has been selected.

- The status can remain as In Stock Only.

Select Source Warehouse

- Select the source warehouse (the warehouse where the A or B-Class item is currently stored).

- In this image, KZN Main has been selected.

Select A or B-Class Item for Transfer

- Click on the item line of the A or B-Class item you wish to transfer.

- In this image an A-Class item has been selected.

- Drag and drop this line into the Selected Items frame.

- The Selected Items frame will now contain a copy of the A -Class item line.

- Click on Stock Transfer.

Parts Data Grid

Add the details as explained above in the Transfer C-Class Item to a Different Site Warehouse process above.

Quantity

- You will note that:

- The Quantity field displays 0. (Unlike C-Class items, where this field is initially populated with the entire amount of the items available in the selected warehouse bin).

- The Average Unit Cost field displays 0.

- Click in the BatchSerialNo field.

Select Item to transfer

- An ellipsis button will be revealed. Click on this button to display the Select a batch//serial no. for this transfer pop up screen.

- You will see that you will only be able to select one (Quantity) item at a time.

- As this is an A or B-Class item, you will see that this screen lists the Serial Nos.

- Click on the row selector in front of the item you wish to transfer.

- Click on Ok.

- The Quantity field will now populate with 1 (only one A or B-Class item can be selected at a time) and the Average Unit Cost field will now populate according to the cost of the selected serial no.

Select Destination Bin

- If not already populated (if, for example there is more than one bin in the destination warehouse) then select the Destination Bin name at this point.

- Click on Save.

- A Part Transfer Processing message box will pop up informing you that -

- Part Transfer No. [ ] saved successfully.

- Click on OK.

Print Transfer Note

- A Report Generation message box will pop up asking -

- Do you want to print the transfer [ ]?

- Click on Yes.

The Report Preview screen will be displayed.

- In this image you can see that the selected A-Class item has pulled through to the Part Transfer Note.

- From here you can View, Print, Export or Email the document.

- Note that the item is being transferred from the original warehouse and bin,

- to the selected destination warehouse and bin.

- Close the Report Preview screen when done.

- You will return to the Stock Status screen.

View A or B-Class Item in Destination Warehouse

- To view the A-Class item in the Destination Warehouse, follow the View the C-Class item in the Destination Warehouse process.

MNU.037.011