Inventory

Auto Order

Application Requirements

The RSI_StatStock application needs to be installed and configured. This is an application that should be linked in the server's Windows Task Manager to execute every evening.

Company Configuration - Stock Management Configuration

-

The following needs to be configured in BPO:

- The Usage Based check box must be selected.

- The Auto Generate check box must be selected.

- The Averaging Period must be set to the number of periods (months) over which the system will calculate average values from the stock transactions.

Inventory Configuration - Stock Control

-

The following needs to be configured per inventory item that needs to be auto reordered:

- The Re-order Method needs to be set-up as min/max and a min and max stock quantity needs to captured.

- The Days in Stock field needs to be inputted with the number of days demand that the stock level is required to meet. i.e. if enough stock on hand is required for 10 days in advance then input a value of 10.

- The Auto Order field needs to be checked (ticked) if the stock item is to be auto reordered. If this is unchecked the system will exclude this item when calculating reorder levels.

Each inventory item that needs to be auto reordered must be configured.

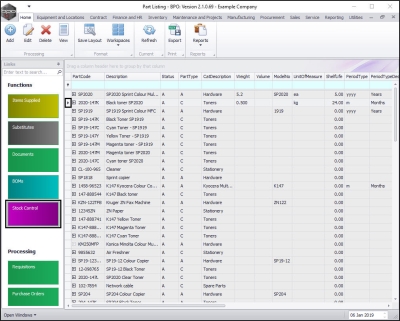

| Ribbon Access: Inventory > Parts |

The Part Listing screen will be displayed,

Select Part

- Select the row of the Part that you wish to configure.

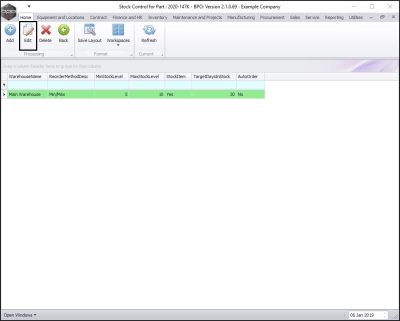

Select Stock Control

- Click on the Stock Control tile.

- The Stock Control for Part: [ ] screen will be displayed.

- Click on Edit.

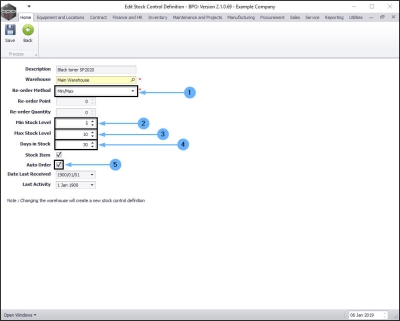

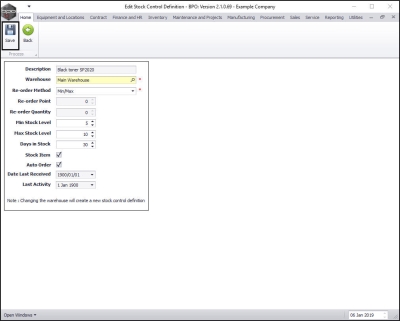

Edit Stock Control to Auto Order

The Edit Stock Control Definition screen will be displayed.

- Re-order Method: Click on the drop-down arrow and select Min/Max.

- Min Stock Level: Click in this text box and either type in or use the arrow indicators to select a minimum stock level quantity.

- Max Stock Level: Click in this text box and either type in or use the arrow indicators to select a maximum stock level quantity.

- Days in Stock: Click in this text box and either type in or use the arrow indicators to select the number of days demand that the stock level is required to meet.

- For Example: If enough stock on hand is required for 10 days in advance then input a value of 10.

- Auto Order: The auto order field needs to be checked (ticked) if the stock item is to be auto reordered.

- (If this is un-checked, the system will exclude this item when calculating reorder levels

Save Changes

- When you have finished editing these details, click on Save.

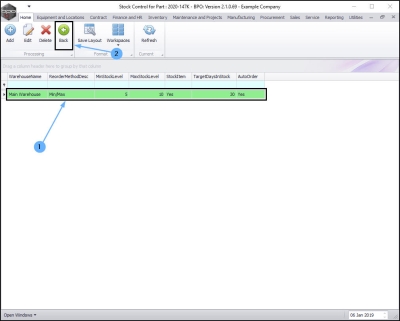

View Stock Control Details

- You will return to the Stock Control for Part: [ ] screen where you can now view the saved stock control details.

- Click on Back to return to the Part Listing screen.

System Calculation for Re-Ordering

How does the system calculate the reorder quantities?

-

The system takes the

following factors into consideration when calculating the optimal reorder

quantity:

- The current stock on hand.

- Average daily usage calculated over the averaging period.

- The lead time from order to delivery.

- Target days in stock required.

-

The following is an example:

|

Inventory Item ABC123: |

|

|

Averaging Period |

6 periods |

|

Current Date |

1 June 2013 |

|

Lead time from supplier |

5 days |

|

Current Stock on Hand |

320 |

|

Target days in stock |

25 |

|

Transactions: |

|

|

Receipt - 1 Jan 2013 |

1000 items |

|

Issue – 20 Jan 2013 |

200 items |

|

Issue – 2 Feb 2013 |

100 items |

|

Issue – 5 Apr 2013 |

380 items |

-

From the above data the order quantity will be calculated as follows:

|

Average Usage per day |

Total Qty (all issues, transfers and returns in averaging period / no. of days between the above transactions) |

(680 /94) |

7.23 |

|

Target Quantity |

Target Days in stock x Average Usage per day |

25 x 7 |

175 |

|

Current Days Stock Holding |

Stock on Hand / Average Usage |

320 / 7 |

45.71 |

|

Date which Min Stock Level will be Reached |

Target Quantity / Average Usage (If no Target Quantity then uses Min Quantity) |

175 / 7 = 25 days from now |

26 June 2013 |

|

Delivery Date |

Today plus Lead Time |

1 June + 5 days |

6 June 2013 |

|

Optimal Order Qty |

Average Usage x (lead time + days difference between date min stock reached and delivery date) |

7 x (5 + 20 days) |

175 |

-

A purchase requisition will

be created for 175 items.

Important Notes:

One purchase requisition is created per warehouse with multiple line items per part code. The purchase requisition can be amended and line items can be deleted or edited.

The supplier on the purchase requisition will be the

primary supplier![]() This will be the supplier that you regularly buy a particular part/item from. The primary supplier is linked to the part definition. Any purchase requisitions raised for this part definition will be created with the primary suppliers details linked. The purchase requisition can be edited to link an alternative supplier, if required. on the inventory item.

This will be the supplier that you regularly buy a particular part/item from. The primary supplier is linked to the part definition. Any purchase requisitions raised for this part definition will be created with the primary suppliers details linked. The purchase requisition can be edited to link an alternative supplier, if required. on the inventory item.

When calculating the reorder quantity the system does not take into consideration existing purchase requisitions or purchase orders. It is important to check that a purchase requisition / order does not already exist for an item before approving a new requisition. (Make sure you run the stock obsolescence report to ensure stock with no usage is not ordered).

If there has been no usage on a specific item for the averaging period and the item is set to auto reorder and the quantity on hand is less than the minimum quantity a requisition will be created to replenish the item to the minimum quantity. It is therefore important not to set items that are not being used to auto reorder or change the minimum quantity to zero.

The system will also check that the order quantity is not less than the minimum order quantity with the supplier and amend the order quantity accordingly.

The system will also check the units of purchase from the supplier. If the optimal reorder quantity is 80 and the units of purchase from the supplier are 50 a requisition will be created for 2 x 50 = 100 items.

MNU.054.004