We are currently updating our site; thank you for your patience.

SConnect

Receiving Stock

- Using a Handheld Scanner running on Windows CE5 and SConnect, you can scan stock you have received from a Supplier into BPO.

- Ensure the bar code is linked to the part code.

- Once items have been scanned, and the GRN is saved from the Handheld Scanner, the Goods Received Note is processed in BPO as it would via the Delivery Items screen.

- The Supplier Invoicing must still be processed as normal on BPO (Add Supplier Invoice and Approve Supplier Invoice).

View Open Purchase Orders

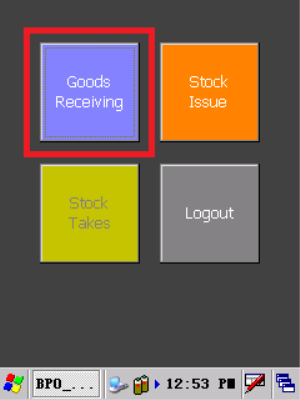

- Select 'Goods Receiving'

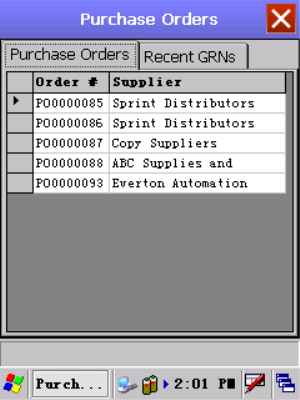

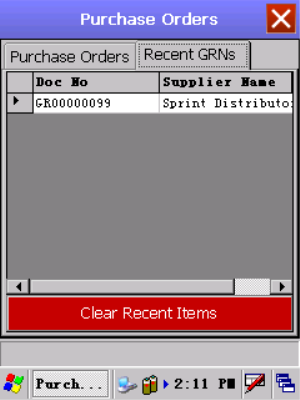

- The 'Purchase Orders' screen will open, displaying 2 tabs.

- 'Purchase Orders' tab: displays all Purchase Orders that need to be received, with the Purchase Order Number and Supplier Name

- Select the PO where stock needs to be received.

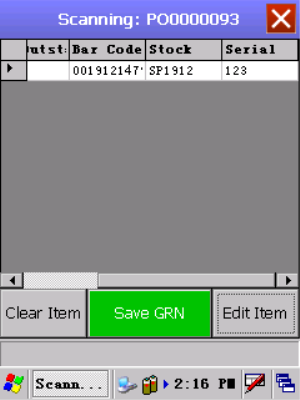

Scan Serialised Items

(A Class and B Class Items)

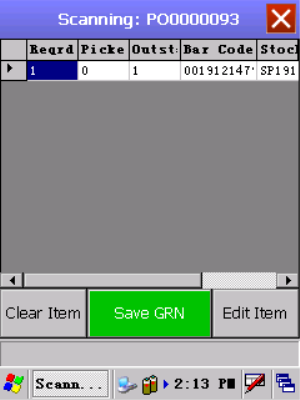

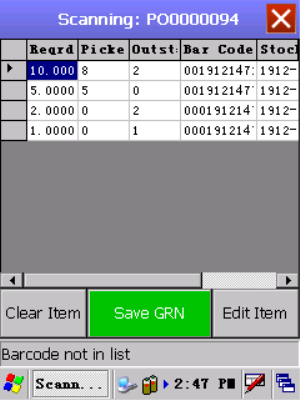

- You will see the following fields:

- Reqrd: Quantity to be Received

- Picked: Quantity Scanned

- Outstanding: Quantity remaining to scan

- Bar Code: Inventory Barcode

- Stock: Part Number

- Serial: Serial Number scanned (if A-class part)

- Remember that A-Class and B-Class Items will display 1 line per serial number required (if you purchased 5 x SP1912 machines - you will see 5 rows because you need 5 serial numbers).

- Scan the barcode for the part.

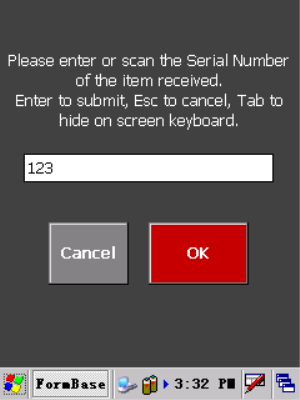

- A screen will come up where you need to input the serial number.

- You can either scan the serial number or type it in.

- Use 'Enter' on the keypad or 'Ok' on screen to submit the serial number to the PO you are scanning.

- You will see the 'Picked' quantity is now set to 1, 'Outstanding' quantity is set to 0, and the Serial Number field is populated with the serial number.

- Continue scanning the barcode and the serial number for each A-Class item you need to received.

- The same applies for C-Class items, except you will be updating quantities received.

- If you did not receive all the Serialised Items, those lines will remain 'un-picked'. Once saved, these will remain on 'back-order', and can be received later.

- When you are done, select 'Save GRN'

Extra

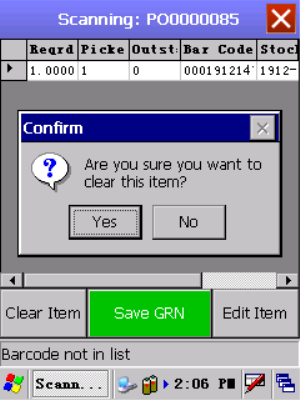

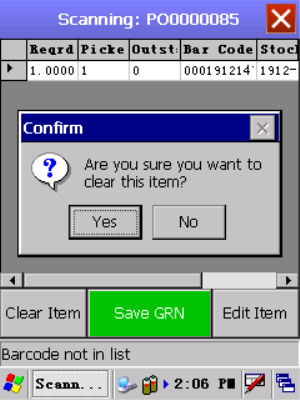

- If you have scanned an item in error: you can

- 'Clear the Item' - this resets to selected line so that you can scan again.

- 'Edit the Item' - this lets you change the serial number (for A-class), or quantity (for C-class).

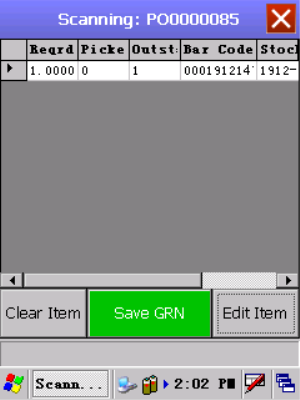

Scan Non-Serialised Items

(C Class Items)

- You will see the following fields:

- Reqrd: Quantity to be Received

- Picked: Quantity Scanned

- Outstanding: Quantity remaining to scan

- Bar Code: Inventory Barcode

- Stock: Part Number

- Scan the barcode for the part.

- A screen will come up where you need to check the quanity received.

- By default, the Required quantity will pull through. If you received less stock, change the quantity.

- Select 'Ok'

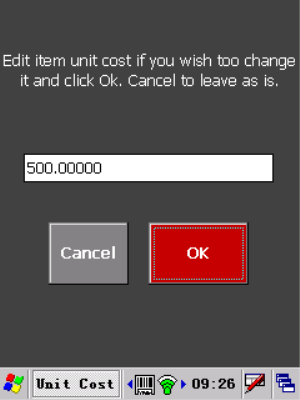

- If you have the security rights for this function, you can check and update the unit cost, if required.

- You will see the 'Picked' quantity is now updated to the quantity scanned.

- Continue scanning the barcode and entering the quantity for each C-Class item you need to received.

- You can partially receive C-Class Items. In this example you will notice the Picked and Outstanding quantity columns displaying what has been scanned and what is still outstanding. (Any items not received will remain on 'Back Order', and can be received later).

- When you are done, select 'Save GRN'

Extra

- If you have scanned an item in error: you can

- 'Clear the Item' - this resets to selected line so that you can scan again.

- 'Edit the Item' - this lets you change the serial number (for A-class), or quantity (for C-class).

View Recently Scanned GRNs

- Select the 'Recent GRNs' tab to view all recent Goods Received Notes.

- This is helpful when you want to go back to BPO to print the GRN.

MNU.154.002