Inventory

Adjust Stock Into Store

If you are using the Stock Batch Tracking option, make sure to select the Batch Number for C-Class (non-serialised) items when adjusting stock. For more details, refer to Inventory: Stock Batches.

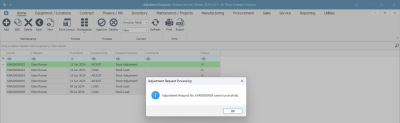

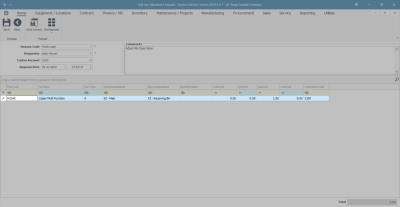

Ribbon Select Inventory > Adjustments

- The Adjustment Requests listing screen will be displayed.

Add New Adjustment

- Select the Site.

- In this image, KwaZulu-Natal has been selected.

- The status will default to New.

- Click on Add

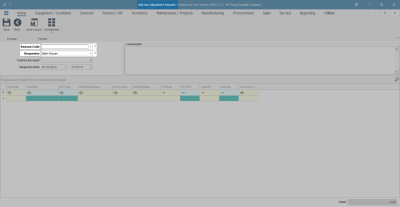

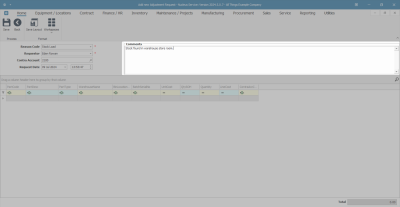

- The Add new Adjustment Request screen will be displayed.

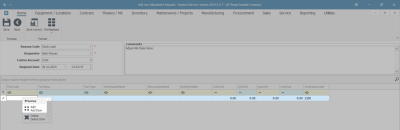

Adjustment Request Reason/Details

- Reason Code: Click on the drop-down arrow and select from the menu the applicable reason code.

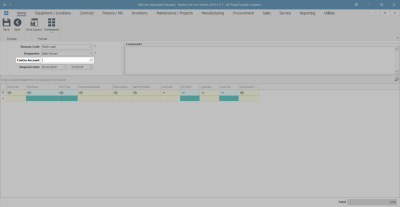

- Requestor: This will auto populate with the person currently logged on to the system. Click on the drop-down arrow and select from the list an alternative person, if required.

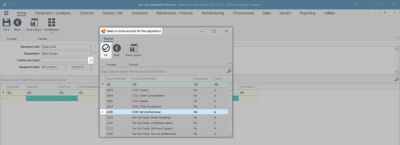

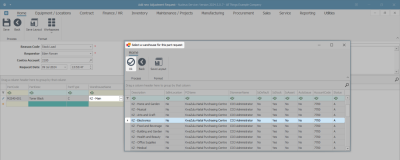

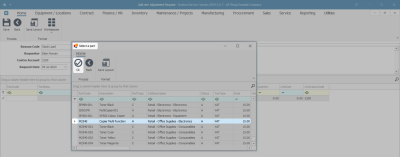

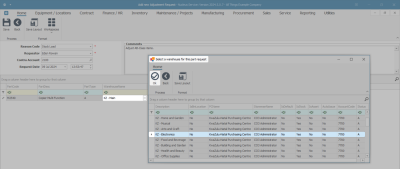

- Contra Account: Click on the search button in this text box.

- The Select a contra account for this adjustment screen will pop up.

- Click on the row of the account number that you wish to link to this adjustment.

- Click on Ok.

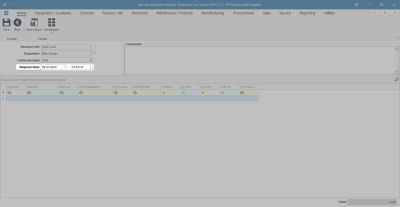

- Request Date and Time: This will populate with the current date and time.

- Date: You can either type in or click on the drop-down arrow and use the calendar function to select an alternative date if required.

- Time: You can either type in or click on the arrow indicators to select an alternative time if required.

Request Comments

- Comments: Click in this text box and type in a comment relating to this adjustment.

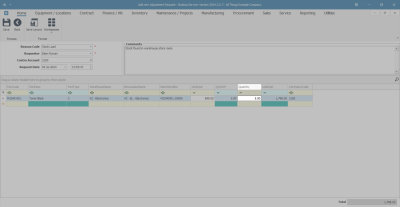

Request Parts/Items Frame

- Method 1

- Click in the Part Code text box. (As you click in this field, the Contra Account Code text box will populate with the previously selected Contra Account Code.)

- An Ellipsis button will be revealed.

- Click on this button to display the Select a part pop-up screen.

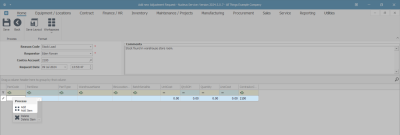

- Method 2

- In the Parts / Items frame, right click anywhere in a row of this data grid. (As you click in this field, the Contra Account Code text box will populate with the previously selected Contra Account Code.)

- A Process menu will pop up.

- Click on Add - Add Item to display the Select a part pop-up screen.

Stock Adjustment - C-Class Items

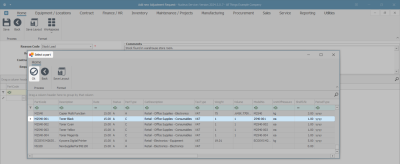

- In the Select a part pop-up screen.

- Select the row of the C-Class part/item that you wish to adjust into store.

- Click on Ok.

- The row will now populate with the Part Code, Part Description, and Part Type details.

- Note: The Quantity column will populate with 1, but this number can be changed only for C-Class items when you move along this row adjusting the details as required.

A-Class and B-Class serialised items can only be adjusted one item at a time, so the quantity will always be 1.

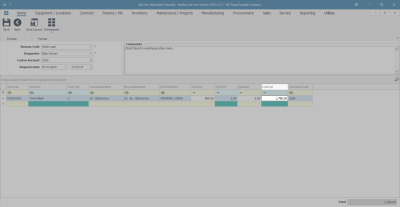

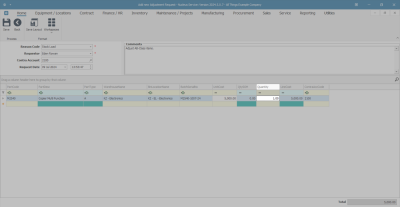

Select Warehouse and Bin

- If the warehouse does not auto populate or if you want to change the warehouse, do the following:

- Click in the Warehouse Name text box.

- An ellipsis button will be revealed.

- Click on this button.

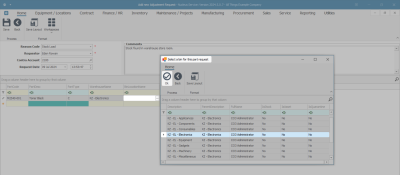

- The Select a Warehouse for this part request screen will pop up.

- Click on the row of the Warehouse where you wish to store this item/part.

- Click on Ok.

- Click in the Bin Location Name text box.

- An ellipsis button will be revealed.

- Click on this button.

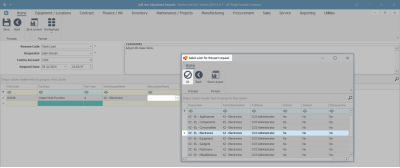

- The Select a bin for this part request screen will pop up.

- Note: If there is only one bin linked to the selected warehouse then the BinLocationName field will populate with that one bin name. Otherwise the Select screen will pop up.

- Click on the row of the Bin Location where you wish to store this item/part.

- Click on Ok.

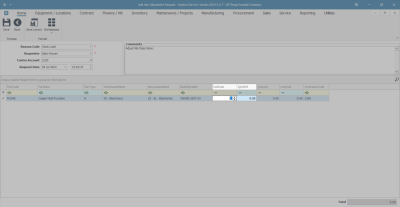

Select Batch/Serial Number

- Click in the Batch Number text box.

- An ellipsis button will be revealed.

- Click on this button.

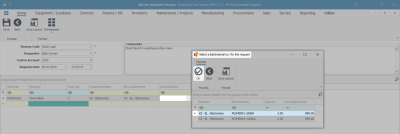

- The Select a batch//serial no. for this request screen will pop up.

- Click on the row of the batch/serial numberthat you wish to adjust.

- Click on Ok.

- Unit Cost: This will auto populate with the cost of the selected part once the batch/serial number has been selected.

- Qty SOH: This is the current Stock on Hand quantity and auto populates when the batch/serial number has been selected.

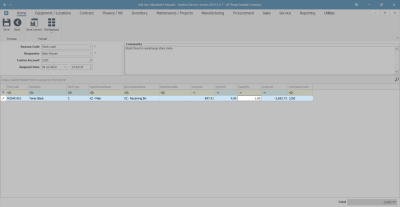

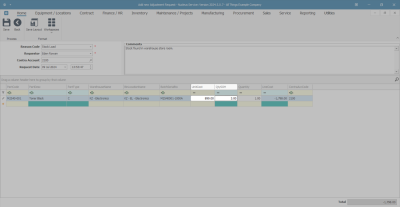

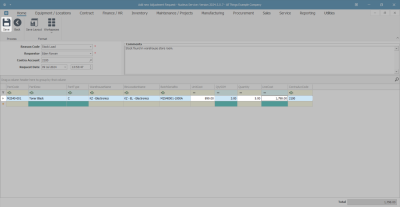

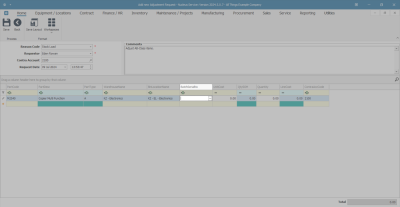

Select Quantity

- Quantity: Type in or use the arrow indicators to select the end stock on hand quantity, i.e., the quantity of stock you'll have after the adjustment is complete.

(Example: Currently 3 in stock, adjusting in 2, Quantity must be 5). - Note: A-Class and B-Class serialised items can only be adjusted one item at a time, so the quantity will always be 1.

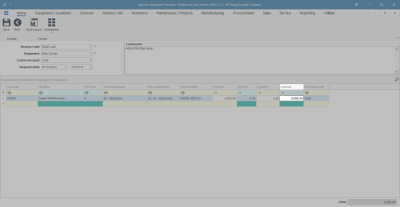

Line Cost for C-Class Item

- Line Cost: The system will auto calculate the sum of the unit cost x the quantity. (In this case, 899 Unit Cost x 5 Quantity = 1798 Line Cost).

- In the new row you can add more items to the list if required.

- Note: You cannot adjust multiple line items of the same part number in one adjustment for C-Class items.

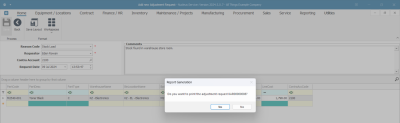

Save Request

- When you have finished adding the adjustment request items, click on Save.

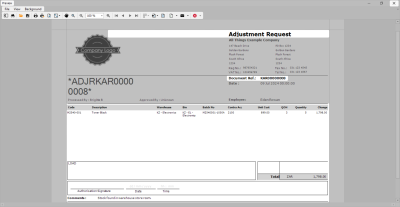

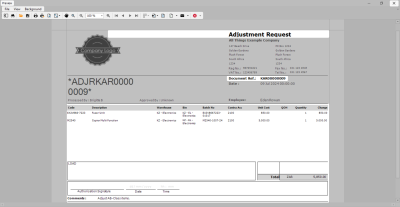

Print Request

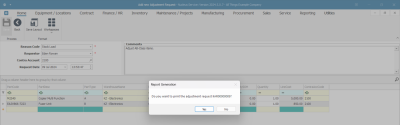

- A Report Generation message box will pop up asking:

- Do you want to print the adjustment request [ ]?

- Click on Yes.

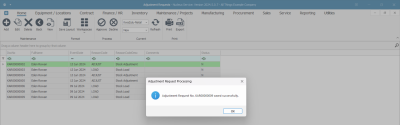

- You will return to the Adjustment Requests listing screen.

- An Adjustment Request Processing message box will pop up informing you that -

- Adjustment Request No. [ ] saved successfully.

- Click on OK.

- You can then view the Adjustment Request report preview screen.

- From here you can View, Print, Export or Email.

- Close the report preview screen when done.

Authorise Request

- Note: This request must be authorised before the Stock Adjustment is completed.

Stock Adjustment A / B-Class Item

- Method 1

- Click in the Part Code text box. (As you click in this field, the Contra Account Code text box will populate with the previously selected Contra Account Code.)

- An Ellipsis button will be revealed.

- Click on this button for the Select a part screen to open.

- Method 2

- In the Parts / Items frame, right click anywhere in a row of this data grid. (As you click in this field, the Contra Account Code text box will populate with the previously selected Contra Account Code.)

- A Process menu will pop up.

- Click on Add - Add Item for the Select a part screen to open.

- In the Select a part screen.

- Select the row of the A/B-Class part/item that you wish to adjust into store.

- Click on Ok.

- The row will now populate with the Part Code, Part Description, and Part Type details.

- Note: The Quantity column will populate with 1 but this number can be changed only for C-Class items when you move along this row adjusting the details as required.

A-Class and B-Class serialised items can only be adjusted one item at a time, so the quantity will always be 1.

Select Warehouse and Bin for A / B-Class Item

- If the warehouse does not auto populate or if you want to change the warehouse, click in the Warehouse Name text box.

- An ellipsis button will be revealed.

- The Select a Warehouse for this part request screen will pop up.

- Click on the row of the Warehouse where you wish to store this item/part.

- Click on Ok.

- Click in the Bin Location Name text box.

- An ellipsis button will be revealed.

- Click on this button.

- The Select a bin for this part request screen will pop up.

- Note: If there is only one bin linked to the selected warehouse then the BinLocationName field will populate with that one bin name. Otherwise the Select screen will pop up.

- Click on the row of the Bin Location where you wish to store this item/part.

- Click on Ok.

Batch/Serial Number for A / B-Class Item

- Click in the Batch Number text box.

- Type in the Serial No of the part you want to adjust into stock.

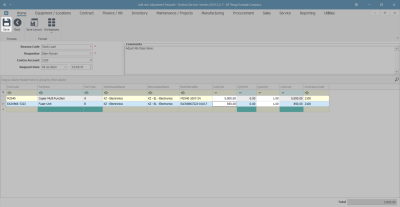

Unit Cost and Quantity Stock on Hand for A / B-Class Item

- Unit Cost: Type in the unit cost of this part.

- Qty SOH: This is the current Stock on Hand quantity and will always auto populate as 0 for A/B-Class items since each item has a unique serial number.

Quantity for A / B-Class Item

- Quantity: The quantity will always auto populate as 1 for A / B-Class items since each item has a unique serial number.

Line Cost for A / B-Class Item

- Line Cost: The system will auto calculate the sum of the unit cost x the quantity. (In this case, 5 000 Unit Cost x 1 Quantity = 5 000 Line Cost). For A / B-Class items, the Line Cost will always be equal to the Unit Cost.

- Add more items in the new row if required.

- Note: You can adjust multiple line items of the same part number in one adjustment for A/B-Class items.

Save Adjustment Request - A / B-Class Item

- When you have finished adding the adjustment request items, click on Save.

Print Adjustment Request - A / B-Class Item

- A Report Generation message box will pop up asking:

- Do you want to print the adjustment request [ ]?

- Click on Yes.

- You will return to the Adjustment Requests listing screen.

- An Adjustment Request Processing message box will pop up informing you that -

- Adjustment Request No. [ ] saved successfully.

- Click on OK.

- You can then view the Adjustment Request report preview screen.

- From here you can View, Print, Export or Email the Adjustment Request.

- Close the report preview screen when done.

Authorise Request

- Note: This request must be authorised before the Stock Adjustment is completed.

MNU.131.002